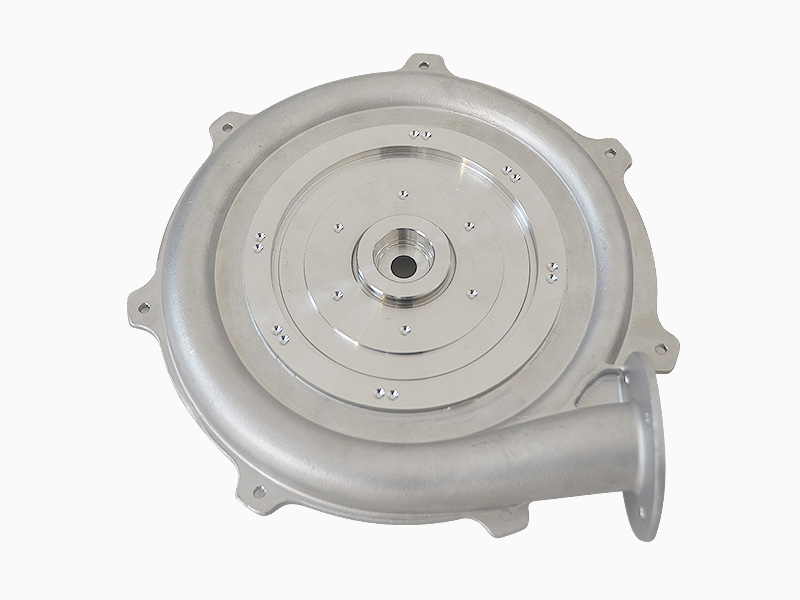

Silica Sol Precision Casting Products

[Main business] The company's main production processes are: silica sol precision casting, water glass precision casting, precision die forging, specializing in the production of precision castings and precision forgings and finished products of carbon steel, alloy steel, stainless steel and other materials. Processing equipment includes dozens of machining centers, CNC lathes, CNC milling machines, CNC grinding machines and other processing equipment; professional testing and inspection equipment such as: three-coordinate measuring instrument, spectrometer, magnetic particle flaw detector, etc. Strict management system ensures the quality of products . Yuankun constantly pursues excellence, innovates and creates high-quality products, and always provides customers with the best quality products.

[Enterprise Qualification] The company has passed the ISO9001:2015 quality system certification, and can skillfully implement the technical requirements of the national standard GB, American standard ASTM, AISI, German standard DIN, French standard NF, Japanese standard JIS, British standard BS, Austrian standard AS and other technical requirements. The company's main products include more than 1,000 kinds of elevator safety accessories, power accessories, auto accessories, railway accessories, building components, auto parts, agricultural machinery parts, medical equipment and construction machinery accessories. According to the requirements of different users to undertake the processing and production of drawings and samples.

[Enterprise purpose] Yuankun Machinery takes the customer first as its purpose, strives for survival with quality, and seeks development with integrity. We sincerely welcome friends from all walks of life at home and abroad to visit the factory to discuss cooperation and create a win-win situation.

[Process introduction] Silica sol (colloidal silica), also known as silicic acid solution, is a colloidal dispersion of amorphous silica aggregate particles in water. Silica sol has a wide water loss temperature range, which not only destroys its bonding strength, but also makes its three-dimensional structure more stable, resulting in higher bonding strength. It is a good inorganic binder for precision casting.

In the 1960s, silica sol began to be used as a binder for precision casting. Since the 1990s, due to the increasing pressure of environmental protection, silica sol has gradually replaced the widely used highly polluted and expensive ethyl silicate hydrolyzate. At present, polymer-enhanced quick-drying silica sol is widely used as a binder in the world investment casting industry.

Precision casting refers to the general term for the process of obtaining castings with precise dimensions. Investment casting is also known as lost wax casting. Its products are precise and complex, close to the final shape of the part, and can be used directly without machining or a small amount of machining. This is an advanced near-net-shape process. The process includes: selecting a suitable investment material (such as paraffin) to make the investment; repeating the steps of dipping the refractory coating (the main component is silica sol) and spraying the refractory sand on the investment, hardening the outer shell and drying; melting the inner investment, Obtain the mold cavity; bake the shell to obtain sufficient strength and burn off the remaining investment material; pour the required metal material; solidify, cool, shell, and clean the sand to obtain a high-precision finished product.

Silica sol is used for precision casting. Due to its good bonding ability and filling performance, the fabricated shell has high strength, high gloss and easy demoulding, and is widely used in this field. According to the specific use requirements, it is divided into surface silica sol and back silica sol, which consumes a lot of money.

Recommended Products

Please keep in touch if you have any questions. We would love to hear from you.